Integrated hierarchy of control

Traditional Hierarchy of Control

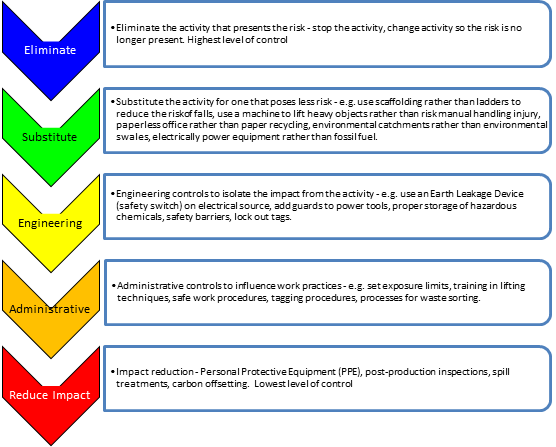

Management system specialists are all familiar with the hierarchy of control as defined by most health and safety systems as:

- Eliminate

- Substitute

- Engineering Controls

- Administrative

- PPE

More details about this traditional hierarchy and how to use it are available here: https://en.wikipedia.org/wiki/Hierarchy_of_hazard_controls

Problem with the traditional hierarchy

The traditional hierarchy can also be applied to quality and environmental management, except for the last term, PPE. PPE (personal protective equipment) is a safety term. We must amend this term to use the hierarchy of control in a meaningful way for the other disciplines. But how?

Breaking it down

The first three items on the hierarchy of control aim to prevent people’s exposure to risk. The last two items on the hierarchy of control, administrative controls, and PPE accept the exposure occurs. And as the exposure is accepted they are the least preferred controls. This is why they are termed below-the-line controls. These controls alone will not keep people safe.

What is PPE for?

Consider what PPE is, how we use it and it’ll be obvious how to adjust the hierarchy of control. PPE accepts that people will be in the ‘line of fire’, that the exposure will occur. Its sole aim is to lessen the impact of the risk exposure.

Let’s look at some examples:

- The purpose of a hard hat is to reduce the impact if someone gets hit on the head.

- Breathing apparatus is used by a person who is entering a dangerous atmosphere.

- People wear steel-toed boots to prevent broken toes if something is dropped.

In all the above cases, the risk exposure is real and likely, but we are trying to reduce the consequences. Another example is a high-viz vest. We class high-viz vests as PPE, but they are actually signs. And signs are administrative controls. It is a sign you wear to prevent a vehicle hitting you.

Integrated Hierarchy of Control

If we accept that real PPE is about minimising the consequences of accepted exposures, then the title Impact Reduction or Consequence Reduction makes much more sense. And this new title makes much more sense for quality and environmental management too. We can now use this more general hierarchy of control for almost any risk including sales and marketing, business continuity, human resources, etcetera.

Want more?

Combining the learning from this article with the Prioritising risks and opportunities on the same scale allows a single methodology for the management of safety, environmental, and quality risks and opportunities.

This is just one way to simplify your management system. We have many more. Contact us for more information or book a Free 1-hour consultation today.